|

The purpose of the head

gasket is more than just to create a seal between head and the deck of

the block.

It acts as

1) a guide for coolant

flow between the block and the head and

2) to promote heat

transfer between them.

The head itself is also

a conduit for coolant transfer to the radiator. Most older sportscars

use gaskets that are made from a sandwich of very thin copper, a

thicker fiber layer (typically asbestos laden) and thin steel. This

gasket design makes it difficult to personally customize for racing

applications and is inherently weak. It is also hazardous to your

health if broken and the fibers are aerosolized and inhaled.

Heat is produced by the

engine almost entirely at the combustion chamber. Coolant flows from

the radiator to the block where it is pre-heated before it goes to the

head where the temperatures are the greatest. The coolant then flows

through the head to the radiator where it looses heat. Water is the

heat sink of choice since it has the highest specific heat capacity.

In order for the coolant

to be functionally efficient it needs to move in-mass from the rear of

the head forward. Most engines have coolant holes in the gasket spaced

from one end to the other. These gaskets allow the coolant to percolate

through to the head less optimally. Generally, there are smaller

coolant holes in the gasket place forward which are needed primarily

for gaseous escape routes and less so for cooling purposes. Since

racing engines produce more heat it would seem intuitive that the flow

through the gasket be channeled to maximize cooling efficiency by

having more of the coolant flow through the rear of the head. It should

also be stated that the flow of the coolant has to be such that there

is an adequate dwell time within the head to adequetly absorb heat.

Additionally, the coolant should be free of any insulating contaminants

such as air (in the form of micro-bubbles) that would preclude ideal

heat conductance. Engines like to run efficiently at an optimal

temperature typically above 180F but less than 220F. Running an engine

hard prior to proper temperature is not good.

Torquing:

This can be a problem at

times. It is critical that the fasteners you are using are better than

"nominal". Use the best you can afford. A key factor that is not

considered often is that the fasteners not only hold down the head but

also PULL-UP on the block.

The torquing procedure

works in two locations

1) on the head side and

the

2) block side.

The threads within the

block maybe weak. Some spots within the block are weaker than others

-depending upon how much metal is around them. When these weaker spots

are stressed they "give" more than other areas. This can actually

deform the block and dimple the deck surface a bit. This

under-appreciated problem can create sealing dillemas. One method used

to mitigate against this effect is to study each motor and relieve

(chamfer) the holes where the fastener enters the block.

Bolt loading:

When a bolt is tightened

a large portion of the tightening torque is used to overcome the

resistance of the threads. Only about 20% (at most) of the torque is

transmitted in tension to the fastener. An important factor in this is

the surface finish of the threads. Some aftermarket fastener

manufatures coat the fastener with a laquer based material that

requires a high quality moly lubricant to be placed on the threads for

proper torquing. If this is not done improper tightening will occurr.

If you wish to use an oil on the threads for torquing - you need to

remove this coating with a wire brush.

EXCESSIVE bolt loading

will cause problems.

Many backyard mecanics

think that if 50 Ft. lbs of torque is good then 60 is better. In fact

dynomometer testing has shown that less is best in most instances.

Indeed extra horsepower maybe gotten by being "torque frugal". Why???

The more torque that is applied onto the block the more chance of

distortion. This distortion is usually seen at the weakest places at

the narrowes point of the bore and at the top of the cylinder. At the

top of the cylinder where the compression pressures are always greatest

any excess distortion will nullify any benefit of that extra clamping

force. Blow-by of gasses will cause premature gasket burn through and

less horsepower. "Less maybe best".

SURFACE FINISH:

The ideal situation is

to have a finish on the flange surfaces (head and block deck) as smooth

as possible. In older engines the typical surface finish was make buy

using a fly cutter on a mill that created symmetric arcing lines. This

finish was good for composit gaskets. The idea being that there was

some imperfection in the surface so that it would "grab and hold' the

gasket in place. Modern motors have bi-metal engines typically. Cast

iron blocks and aluminum heads. These have different heat

characteristics and therefore stretch at different rates. If these

surfaces had the typical finish of yesteryear the gasket would fail due

to shearing effects. Newer motors have very smooth finishes -in fact

most machine shops don't have (but will have to eventually) the

equipment to produce this finish.

When using copper

gaskets in any motor ask your machine shop to get an RA (roughness

average in Microinches) of about 60 for cast iron heads and blocks and

closer to 40 for aluminum.

Compression Ratio:

Definition; Compression

ratio is the volume of the space above the piston at BOTTOM dead center

and the volume of the space above the piston at TOP dead center.

In order to figure out

the compression ratio several volumes are needed to make the final

calculation.

1) Combustion chamber

volume: This volume is the space within the head that the piston pushes

the charge of air/fuel into. Typically, people refer to this as

"cc'ing" the head. It requires an accurate burrette, a piece of clear

glass or plexiglass with a hole (to allow you to place colored alcohol

or solvent into the space), some grease and a finnished head with the

valves installed. Apply the grease to the valve seats and allow the

valve springs to seal them into place. Wipe off any extra grease from

the combustion chamber. Lay the head so that the combustion chamber is

face up. Place some grease upon the surface around the opening and

place the clear plastic plate upon it. Slide the plate and press firmly

to get a good seal. Add fluid into the chamber through the hole of the

plastic plate and fill the chamber. You need to be exact. Get rid of

any air bubbles by tapping the head. Make sure no fluid leaks from

around the valves. The amount of fluid you add to this space is the

COMBUSTION CHAMBER VOLUME. Do this for each cylinder. Use the same type

of fluid in each chamber measurement. Do Not use

alcohol in one and solvent in another.

2) Dome Volume: under

construction.....

3) Piston Deck

height:......."

4) Gasket Volume:......"

5) Valve reliefe

volume:....... "

Making Head Gaskets Last

Subaru head gaskets are

about as hot of a topic as national health care lately. If you own a

Subaru you know what I mean.

Since the 2.5 liter

Subaru engine was put into production there have been thousands of head

gaskets replaced across the country. We’ve done a good portion of those

ourselves. In another post I’ll go into further detail about the

details of Subaru head gaskets but for today I would like to offer some

suggestions on how to help prolong the ones you have.

Subaru head gaskets can

fail for numerous reasons. Failure of sealant, improper torque, surface

imperfections in the cylinder head or engine block and of course heat

or excess heat.

I’m going to focus on

excess heat. Within the engine block the coolant is circulating to keep

the engine cool due to internal combustion occurring. The coolant

remains in contact with the metal and is able to absorb heat, travel to

the radiator and release the heat to the atmosphere.

Two important things

must occur to for the coolant to do it’s job. It must have adequate

flow to move the heat away from the internal areas of the engine and it

must remain in contact with the areas it’s trying to cool.

There are 3 very

important items that may individually have a negative impact on the

coolant’s ability to do it’s job. If all 3 components are bad or

inferior, problems could develop even sooner.

Subaru Radiator Caps OLD

vs NEW

Radiator cap:

Keeps coolant in a

sealed system, allows overflow to exit and return as coolant expands

and contracts, but most importantly it raises the boiling point of the

coolant in the system by keeping the cooling system pressurized. Most

radiator caps for stock vehicles keep the system pressurized between

13-15psi. This can raise the boiling point depending on the mix of

coolant/water an additional 35-40 degrees. A 50/50 mix of anti-freeze

and water has a boiling point around 265 degrees. Add to that a

radiator cap that holds 13psi and now you have coolant that won’t boil

until 300 degrees .

There are areas

throughout the engine where the coolant circulates that become very

hot. So hot that it can boil coolant. Since we must have the coolant in

contact with the metal to perform it’s heat transfer duties we now have

a problem. Scenario: Radiator cap is weak (which we run into all the

time on Subarus). A weak radiator cap not holding pressure may not let

all of the coolant get hot enough to boil but there are areas within

the engine that are now boiling. Boiling coolant has air bubbles that

now keep the coolant from contacting the cylinder walls and other

extremely hot areas within the engine. This heat is more than the

engine and gasket were designed to withstand on a regular basis and

thus a situation that will accelerate the failure of the gasket.

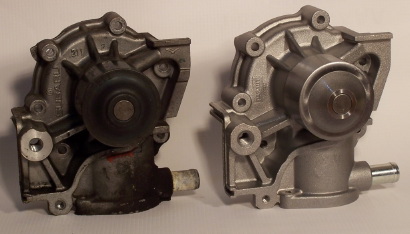

Flow of the coolant is

important also. To keep from boiling the hot coolant must be quickly

moved away from the hot cylinder walls up to the radiator so it can

release it’s heat. Below is a picture of a Subaru water pump and also a

quality Japanese aftermarket water pump. Although we for the most part

believe in genuine Subaru parts, here’s a case where genuine Subaru

part’s may not be the best choice. Note the stamped steel vanes on the

Subaru pump vs the quality cast and machined impeller on the Japanese

counterpart. The tight clearances and defined impeller vanes are very

efficient at moving coolant through your Subaru engine. (an interesting

side note that older Subaru water pumps were made nearly identical to

the pump on the right).

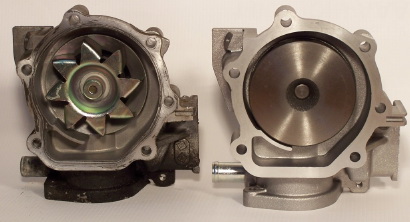

Another important part

of keeping the hot coolant flowing out to the radiator and away from

the internal hot spots in the engine is a high quality thermostat. I’ve

shown below the comparison between a generic aftermarket brand on the

left and a genuine Subaru thermostat on the right.

Note the Subaru version

has a much larger spring, larger diameter central area for coolant flow

and is made of steel and brass. The generic brand contains copper, a

big no no with Subaru. Subaru actually states that copper in a Subaru

cooling system is ill advised and may cause excessive electrolysis and

corrosion.

Even after trying to be diligent about

providing the best possible cooling for your Subaru you still may need

to cross the head gasket bridge some day.

|